Honeycomb cardboard combines innovative design with sustainability, offering strong yet lightweight packaging that meets growing eco-friendly demands. Its unique structure maximises durability while minimising material use, reducing environmental impact. By harnessing renewable resources and ensuring recyclability, this packaging material addresses both protection and planet-friendly concerns, presenting a compelling alternative to traditional options in supply chains and consumer goods industries.

Understanding Honeycomb Cardboard and Its Structure

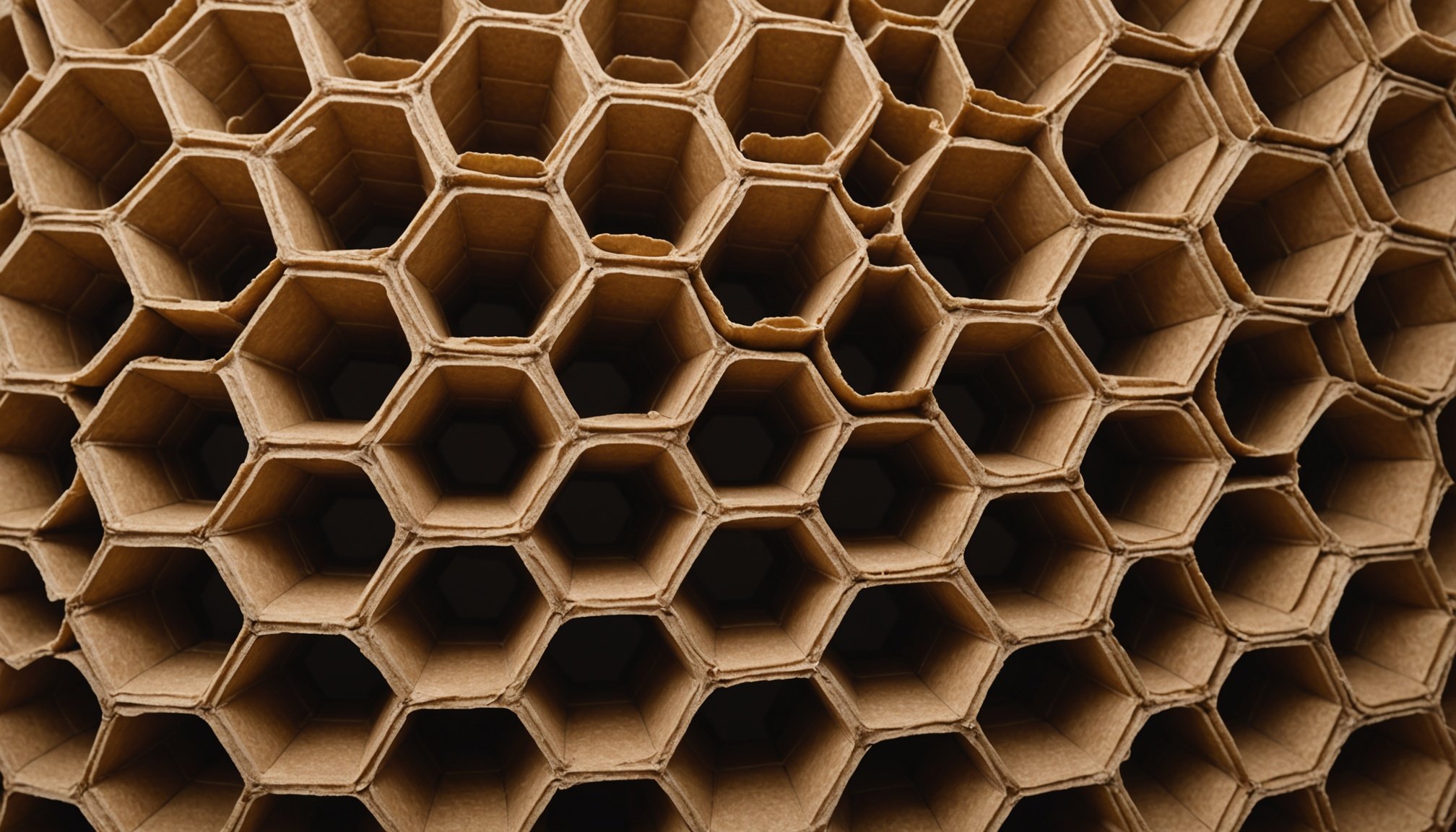

Honeycomb cardboard is an innovative packaging material structure designed to combine strength and lightness in a sustainable way. At its core, this material consists of a series of hexagonal cells arranged in a honeycomb pattern, typically made from layers of paperboard or recycled fiber. These cells create a structure that is both rigid and resilient, providing exceptional cushioning and impact resistance while remaining lightweight.

Have you seen this : What Opportunities Exist for Growth in UK Business Services?

The genius of honeycomb cardboard lies in its structural design. The hexagonal arrangement efficiently distributes pressure and absorbs shocks, making it ideal for protecting fragile items during transit. This design mimics the natural efficiency found in a beehive, which is why it allows for maximum strength with minimal material use. As a result, honeycomb cardboard delivers superior performance compared to traditional flat or corrugated boards but with less environmental impact.

Historically, honeycomb packaging emerged as a response to increased demand for eco-friendly packaging alternatives. Its development gained momentum in the late 20th century as industries sought sustainable solutions to replace plastics and heavy woods in shipping and storage. Continuous innovations have improved both the manufacturing processes and the versatility of honeycomb cardboard, enabling its use across diverse sectors from electronics to furniture.

Also to read : Top tips for choosing a corporate party event agency

For anyone interested in sustainable solutions, understanding the design and benefits of honeycomb cardboard underscores why it is increasingly favored as a packaging material structure that balances durability, efficiency, and environmental responsibility.

Sustainability and Environmental Impact of Honeycomb Cardboard

Honeycomb cardboard is a standout choice in sustainable packaging due to its use of renewable resources. Manufactured primarily from paperboard derived from responsibly managed forests, this material minimizes reliance on non-renewable inputs. The production process itself typically consumes less energy compared to plastics or metal packaging, contributing to its environmental benefits.

One of honeycomb cardboard’s most significant advantages is its biodegradability and recyclability. Unlike many conventional materials, honeycomb cardboard breaks down naturally in composting conditions without leaving harmful residues. Moreover, because it is made from paper fibers, it can be easily recycled using existing paper-recycling infrastructure. This promotes a closed-loop lifecycle, reducing waste and conserving raw materials.

When comparing the carbon footprint of honeycomb cardboard with other common packaging options, the data consistently shows lower greenhouse gas emissions. Producing honeycomb cardboard emits less CO2, making it a practical choice for businesses striving to reduce their environmental impact. Its lightweight structure also lessens transportation emissions, further enhancing its sustainability credentials.

Manufacturing Process of Honeycomb Cardboard

The manufacturing process of honeycomb cardboard centers on transforming raw materials into a strong, lightweight structure through eco-efficient methods. At its core, the process begins with careful material sourcing, prioritizing recycled papers and sustainable fibers. This ensures a reduction in environmental footprint from the outset.

Once sourced, the raw paper materials are cut into strips and formed into the characteristic hexagonal honeycomb cores. These cores are then bonded between linerboards, producing panels that combine strength and flexibility. This bonding step uses adhesives designed to be environmentally friendly, further supporting eco-manufacturing principles.

To maintain high quality, manufacturers incorporate rigorous quality control measures throughout. This involves tests to assess the board’s compression strength, durability, and consistency. Such procedures ensure the honeycomb cardboard meets performance standards while adhering to sustainability goals.

Ultimately, the reduction of environmental impact during manufacturing is achieved by optimizing energy use and minimizing waste. Many producers recycle excess materials back into the production cycle, exemplifying a closed-loop system. This approach not only preserves resources but also highlights honeycomb cardboard as a leading choice in sustainable packaging solutions.

Common Applications in Packaging

Honeycomb cardboard has established itself as a versatile player in packaging solutions across industries. Its lightweight yet robust structure provides superior product protection, making it a preferred choice for shipping and handling fragile or heavy items alike.

This material excels in cushioning products during transit, reducing damage rates significantly. The honeycomb design absorbs shocks and distributes pressure evenly, which is why it is often used to protect electronics, glassware, and medical devices. Its adaptability allows manufacturers to customize thickness and cell size to match specific packaging needs, enhancing protection without increasing weight excessively.

In terms of application examples, honeycomb cardboard is widely adopted for pallets, partitioning, and corner protection in logistics. Companies that previously relied on foam or solid cardboard often switch to honeycomb cardboard due to its balance of strength, cost-effectiveness, and environmental benefits. Notable case studies include furniture manufacturers who reduce shipping damages, and electronics suppliers who improve unboxing experiences while minimizing waste.

Using honeycomb cardboard in packaging solutions also contributes to sustainability goals, thanks to its recyclability and renewable composition. For those interested in exploring eco-friendly packaging alternatives, understanding the many benefits of honeycomb cardboard can offer practical pathways forward. You can find more details in articles discussing honeycomb cardboard.

Comparison with Alternative Packaging Materials

Exploring material alternatives in eco-friendly packaging

When evaluating alternative packaging materials, honeycomb cardboard emerges as a strong contender, especially when contrasted with traditional options like corrugated cardboard, plastic, and foam. The material comparison hinges on performance, cost, and environmental impact, offering valuable insights for businesses aiming for sustainable packaging solutions.

Honeycomb cardboard offers superior strength-to-weight ratio compared to corrugated cardboard, making it more durable under pressure while often weighing less. This property improves logistics efficiency by reducing shipping costs. Unlike plastic and foam, honeycomb cardboard is biodegradable and recyclable, addressing key eco-friendly options concerns. Plastic, while durable and moisture-resistant, tends to score poorly on environmental impact due to its persistence in ecosystems and challenges in recycling. Foam packaging shares similar environmental drawbacks; it provides cushioning but is often non-biodegradable and difficult to recycle.

From a cost-effectiveness standpoint, honeycomb cardboard is competitive, especially in large-scale applications. Although initial manufacturing costs can be slightly higher than simple corrugated cardboard, the enhanced protection reduces product damage rates, which can lower overall costs. Foam and plastic materials might offer upfront savings but can incur higher disposal or long-term environmental costs.

Choosing between these packaging materials depends strongly on product type and shipment conditions. Honeycomb cardboard excels in protecting fragile items while remaining sustainable. However, for moisture-sensitive goods, plastic may still be preferred due to its water resistance. Foam is often reserved for high-impact protection but lacks environmental benefits.

Overall, considering alternative packaging materials means balancing function, environmental responsibility, and budget. For many applications, honeycomb cardboard’s unique combination of durability and sustainability makes it a compelling choice.

Advantages and Disadvantages of Honeycomb Cardboard

Honeycomb cardboard offers distinct packaging benefits that make it a popular choice in various industries. One core benefit is its exceptional strength-to-weight ratio. The unique honeycomb structure provides remarkable rigidity and load-bearing capacity while maintaining a lightweight profile. This quality translates into significant weight savings, reducing shipping costs and environmental impact. Additionally, honeycomb cardboard is celebrated for its sustainability. Made primarily from recycled paper fibers, it is both recyclable and biodegradable, aligning well with modern eco-conscious packaging strategies.

However, understanding the packaging drawbacks is essential before selecting honeycomb cardboard. Despite its strengths, it may not perform optimally under prolonged exposure to moisture or heavy impact without additional treatment. The open-cell structure can absorb water, weakening its integrity, which limits its use in damp or wet environments. Moreover, when compared to solid corrugated board, its surface may be less smooth, potentially affecting print quality or visual appeal if aesthetic packaging is a priority.

When evaluating the decision factors for honeycomb cardboard packaging, consider the balance between sustainability goals, mechanical requirements, and cost-effectiveness. Its environmental benefits make it ideal for businesses prioritizing green packaging solutions. At the same time, the need for moisture resistance or surface finish quality might require supplementary materials or treatments. Assessing the end-use environment and mechanical demands will guide whether honeycomb cardboard is the best fit.

The Advantages of Honeycomb Cardboard in Sustainable Packaging

Honeycomb cardboard stands out as a versatile and eco-friendly choice in sustainable packaging, offering benefits unmatched by conventional materials. Its unique structure—a series of hexagonal cells—provides exceptional strength and durability while remaining lightweight. This design reduces the amount of raw material needed, significantly lowering environmental impact without compromising protective qualities.

When choosing sustainable packaging, honeycomb cardboard shines due to its renewable nature and recyclability. It is commonly produced from recycled paper products, further contributing to a circular economy by minimizing waste. This material is also biodegradable, meaning it doesn’t contribute to landfill growth the way plastic does.

A frequent question arises: How does honeycomb cardboard compare to other packaging options in terms of protection? The answer lies in its shock-absorbing capability. The honeycomb structure effectively distributes pressure and absorbs impacts, making it ideal for fragile items during shipping. This means fewer damaged goods and less waste, both critical for sustainable business practices.

For industries seeking packaging that balances practicality with environmental stewardship, honeycomb cardboard offers:

- Optimal cushioning for delicate products.

- Reduced carbon footprint due to its lightweight and sustainable composition.

- Cost-efficiency over time, as its durability reduces the need for replacement packaging.

- Versatility, with customizable sizes and thicknesses to suit different product needs.

Incorporating honeycomb cardboard in packaging solutions represents a practical step toward sustainable development goals. Its natural, renewable characteristics paired with mechanical efficiency ensure that companies can protect both their products and the planet.