Honeycomb cardboard combines exceptional strength with lightness, making it ideal for sustainable packaging. It cushions products effectively while reducing weight and waste. Its fully recyclable, renewable nature significantly lowers environmental impact, offering a practical alternative to plastics and wood. Designed for versatility and cost savings, honeycomb packaging meets today’s demand for eco-friendly, efficient solutions across industries.

Essential facts on honeycomb cardboard for packaging and industrial applications

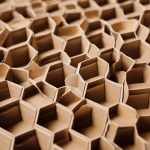

Within industrial and packaging sectors, honeycomb cardboard is widely recognized for delivering a rare balance of strength, lightness, and environmental responsibility. This material stands out in fulfilling rising demand for sustainable packaging solutions as it combines a high strength-to-weight ratio with recyclability. The hexagonal core structure is engineered to deliver stacking strengths up to 8,000 kPa, protecting fragile items during shipping and minimizing risks of crushing or shifting.

Also to read : How Does Brexit Impact British Businesses Today?

The unique honeycomb structure design optimizes both material efficiency and protective performance. Panels are manufactured from virgin Kraft or recycled papers, and are available in thicknesses ranging from just a single millimeter up to 50mm or more, supporting applications from lightweight product cushioning to heavy-duty pallet dividers. The customizable nature ensures that businesses can tailor packaging to fit both their sustainability targets and product protection needs.

Applications go beyond packaging; industries use this innovative material for construction components and flat-pack furniture, where strong yet lightweight panels reduce overall weight without sacrificing integrity. Its 100% recyclability further advances eco-friendly packaging alternatives. You can view more details on this page: honeycomb cardboard.

Topic to read : What Are the Potential Impacts of Emerging Technologies on UK Businesses?

Manufacturing process, structure, and technical characteristics

The honeycomb sheet manufacturing process begins with layering virgin or recycled kraft papers into continuous strips. These strips are bonded in a staggered pattern, then expanded to reveal the hallmark hexagonal honeycomb core. This design maximizes compressive and load-bearing capacity—the compact cells excel at impact resistance and structural strength of honeycomb panels—outperforming conventional corrugated alternatives with less material weight.

Material sourcing is a cornerstone of sustainable packaging solutions. Papers for honeycomb core materials come from forests certified by FSC, PEFC, or SFI standards. Manufacturers prioritize sustainable materials sourcing by using both virgin and recycled content, advancing eco-friendly packaging alternatives without sacrificing performance.

Cardboard honeycomb sheet dimensions offer significant design flexibility. Standard panels come in thicknesses from 8mm to over 50mm, and can be produced up to 2270 x 3200 mm. Custom honeycomb cardboard solutions include tailored cardboard honeycomb sheet dimensions and dual cutting options—supporting supply chain packaging optimization for various industrial packaging uses.

Honeycomb panels withstand heavy-duty application: their honeycomb structure design delivers essential packaging cushioning options and durable shipping materials for everything from protective packaging for fragile items to innovative packaging materials in construction, electronics, and beyond.

Commercial, industrial, and environmental advantages

Honeycomb cardboard stands out for cost-effective packaging solutions due to its exceptional strength-to-weight ratio and advanced honeycomb structure design. Precision SQuAD analysis reveals that, compared to EPS, bubble wrap, wood, and traditional corrugated options, honeycomb cardboard delivers notably better resistance to compression and impact absorption. This flexibility in packaging cushioning options ensures fragile items remain secure, reducing the risk of costly damages during shipping.

Industrial packaging uses show that shifting to honeycomb structure design eliminates the need for ISPM15 certification, cutting regulatory burdens and streamlining export logistics. Lightweight protective packaging allows sizable reductions in freight charges since honeycomb cardboard adds minimal weight to consignments. Custom-fit honeycomb cardboard solutions further minimize packaging waste, helping companies meet modern eco-conscious shipping trends and stricter environmental impact of cardboard packaging requirements.

Reusable packaging options enable businesses in electronics, healthcare, furniture, and logistics to cut resource consumption and support zero-waste targets. Across sectors, market data indicates substantial packaging cost savings when adopting innovative packaging materials like honeycomb paper, driven by improvements in supply chain packaging optimization and enhanced durability against repeated handling. These business gains coincide with rising demand for recyclable packaging materials that further support sustainable packaging solutions.

Applications, innovation, and supplier resources

Cardboard panel applications now extend far beyond basic box packaging. Edge protectors, corner boards, and pallet dividers made from honeycomb cardboard provide exceptional structural strength of honeycomb panels, helping cushion items against impact and minimizing shipping costs through their lightweight nature. In artistic and retail settings, honeycomb panels serve as versatile, strong, and relatively lightweight substrates for custom displays, models, and artwork.

In the industrial sphere, industrial packaging uses include robust pallet solutions, honeycomb board for pallets, and sustainable blocking/bracing. Custom honeycomb cardboard solutions are frequently required—precisely tailored sizes and shapes for electronics, automotive, and healthcare can be produced with minimal tooling costs.

Honeycomb cardboard sheet suppliers such as Smurfit Westrock and RhinoBoard offer an array of recyclable packaging materials to meet business needs across the UK and internationally. Sheets come in a variety of thicknesses and panel sizes, supporting every use from protective packaging for fragile items to creative DIY construction.

Recycling process for honeycomb cardboard is straightforward: these panels are fully recyclable and often made from recycled content. Many suppliers also provide packaging sustainability certifications (FSC®, PEFC™), verifying environmental credentials, which support businesses in meeting eco-conscious shipping trends and regulatory requirements.